The various methods of textile decoration explained along with the pros and cons they have...

Vinyl printing is a digital heat seal transfer decoration method which uses controlled heat and pressure to thermally bond graphics onto the garment. Instead of printing directly onto a fabric, your design is printed on to a material designed to fuse with the garment, it is then heat pressed on to the garment.

- Sharp edges for fine detail

- Reasonably large print area

- Usually quicker lead times

- Ideal for one offs and small quantities

- Large print areas do not irritate the skin

- Can print on pockets of shirts

- Usually no setup charge

- Ideal for sportswear etc.

- Ideal for waterproof clothing

- Special effect vinyl’s available such as a metallic or textured look

- Can’t iron over the print

- Can’t wash or tumble dry at a very high temperature

- Can be restricted to the amount of colours used

- The printed area is not usually breathable

- Can’t print easily on knitwear and fleeces

Screen printing is a printing technique whereby a mesh/screen is used to transfer ink onto the material, except in areas made impermeable to the ink by blocking parts of the mesh/screen. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the material momentarily along a line of contact. This causes the ink to wet the material and be pulled out of the mesh apertures as the screen springs back after the blade has passed. Once the garment has dried the inks should last on a garment or other item through many washes.

- Suitable for larger quantities

- Usually more cost effective on the larger quantities

- Suitable for the multiple coloured or full colour design

- Can be subject to cracking

- Usually there is an initial setup charge for the screens etc.

- Prices tend to increase the more colours you have printed

- The printed area is not usually breathable

- Can’t print on knitwear and fleeces easil

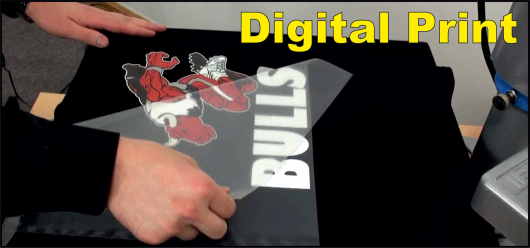

Digital transfer printing or direct to garment (DTG) printing is one of the newer decoration capabilities available in the apparel world, and it is becoming a popular alternative to screen print and embroidery. The detail is superb and can pick up the various shading and colour changes in an intricate design. These are either printed directly on to the garment or on to special film and then heat press to the garment.

- Sharp edges for fine detail

- Usually quicker lead times

- Full colour quality print

- Ideal for one offs and small quantities

- Can print on pockets of shirts

- Usually no setup charge

- Ideal for sportswear etc.

- Ideal for waterproof clothing

- Great for printing photo’s

- Can’t iron over the print

- Can’t wash or tumble dry at a very high temperature

- The printed area is not usually breathable

- Can’t easily print on knitwear and fleeces

Sublimation printing is a decoration style that is reasonably limited in use, as it can generally only be done on 100% white polyester garments so if you require a black garment the black has to be printed all over the material along with the logo or logo’s. It’s a type of printing that uses heat-sensitive inks – under high temperatures, the ink turns to gas and bonds with the fabric or product and becomes part of its physical structure, often used in sportswear.

- The print is absorbed in to the garment

- The printed area is breathable

- The garment can colour match you desired colour as the whole material can be printed

- Can’t launder or dry too hot as colours could migrate

- The print quality tends not to be as sharp as other print methods

- Usually requires printing before garment is manufactured hence larger quantities may be required

- Usually an initial setup charge

- Restricted to the garment material used, ideally needs to be manmade usually 100% white polyester

Embroidery is decorating fabric or other materials using a needle to apply thread or yarn, embroidery is usually seen on caps, hats, coats, blankets, dress shirts, and general workwear. There is another option of woven logo’s which a finer thread is used to include more detail is but usually manufactured separately and then attached to the garment which is another process to consider in the overall cost.

- Very durable

- Add texture to the design or logo

- Has a premium perception

- Harder wearing and would potentially last longer

- Ideal for, workwear, knitwear and fleeces

- Can struggle to produce fine details in a logo

- Can’t do shading or vignettes easily

- Usually more expensive to produce

- Usually an initial setup or digitisation charge

- Expensive for large logo’s

- Can irritate skin if a design is large as the underside can rub

- Can be restricted to the amount of colours used

- Harder to waterproof

- Not ideal for thin materials

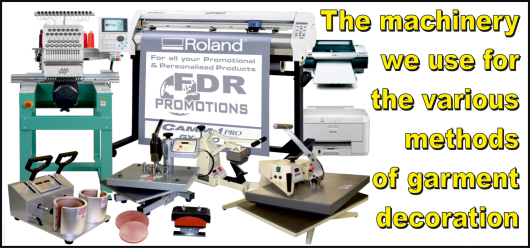

Our Machinery...

Pretty much all the Artwork, Embroidery and Printing is produced in-house giving our customers the reasurance that by dealing with FDR Promotions directly there are no 'middle-men' involved and our prices and lead times will always reflect this.

In order to offer the most competitive prices, we cost each job individually taking into account the quantity and type of garments required together with the size and stitch count of a design.

Our machinery line up consists of:

-

Vinyl Cutters (cutting up to 460mm wide)

-

Heat Presses (for adhering print to the textiles including flat products that can be sublimated)

-

Embroidery Machines (embroider up to 10 coloured threads at once to a logo on to most textiles)

-

Sublimation Printers (producing colour prints for mugs, coasters, t-shirts, metal products, etc.)

-

Cap Heat Presses (capable of printing many styles of caps, hats & sleeves)

-

Pocket & Sleeve Heat Presses (printing to smaller areas)

-

Umbrella Heat Presses (pressing logos to the umbrella panels in both single colour and full colour)

-

Mug Heat Presses (full colour printing to mugs, metal drinks bottles, flasks, travel mugs etc.)

-

Clear Colour Transfer Printer (colour printed logos and images on to white or pastel garments and textiles)

-

Colour Transfer Printer with a White Toner (colour printed logos and images on to dark garments and textiles)

Please remember.

We often offer a free delivery service locally within the Farnborough, Aldershot, Fleet, Camberley, Basingstoke, Bracknell, Guildford, Woking and Farnham areas.

Providing the job is big enough or we are over in your area we are likely to offer the same delivery service further afield too, such as: Alton, Reading, Slough, Staines, Wokingham, Chertsey, Windsor, Weybridge, Godalming, Winchester and the Heathrow area. We also have clients even further afield in London and the home counties, Southampton, Croydon, Portsmouth, Peterfield, Reigate, Maidenhead and cover most of the UK too, so we are not just tied down to our immediate area we can provide a great competitive service where ever you are.